Dia 20mm-150mm Forged Steel Grinding Ball for Mining

High quality Forged Steel Grinding Ball/Grinding Media for Mine DESCRIPTION 1. Grade: 45#,50Mn,60Mn,65Mn,B2,B3,BL,BG2. D;

Basic Info

| Model NO. | B2, B3 |

| Material | Steel |

| Content | >90% |

| Usage | Construction, Chemical, Grind, Mining, Cement Plant |

| Processing Type | Forging, Rolling, Casting |

| Size | Dia 20mm-150mm |

| Color | Brown |

| Customized | Customized |

| Product Name | Forged Steel Grinding Ball |

| Process | Cast & Forged |

| Certification | TUV ISO9001, SGS, ISO14001, OHSAS 18001, BV |

| Service | Free Sample & Customized |

| Free Sample & Customized | Quenching & Tempering |

| Hardness | 56-65 HRC |

| Impact Toughness | >17ak.J/Cm^2 |

| MOQ | Small Quantity Acceptable |

| Material Grade | High Alloying Steel |

| Quality | Guarrantee, Professional Production 30 Years |

| Advantage | Prices, Assure Quality, Shoter Delivery |

| Quality Control | Professional Inspection |

| Transport Package | Flexible Container Bags or Steel Drums |

| Specification | 45#, 50Mn, 60Mn, 65Mn, B2, B3, BL, BG |

| Trademark | SHENGYE |

| Origin | China |

| HS Code | 73261100 |

| Production Capacity | 150000 |

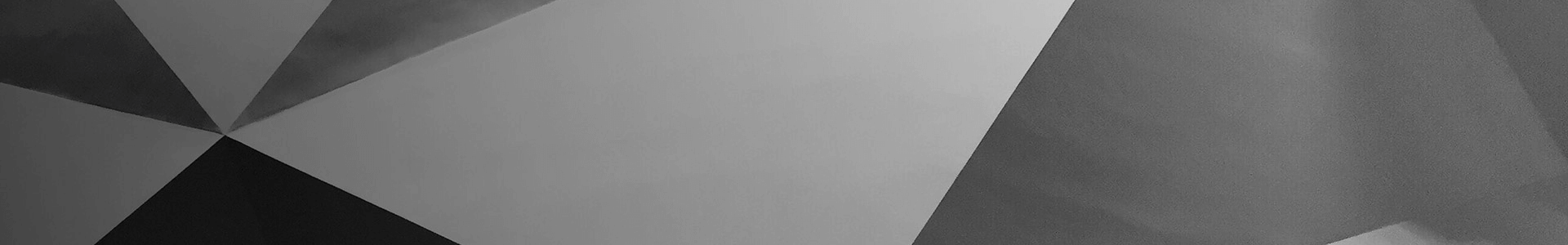

Product Description

High quality Forged Steel Grinding Ball/Grinding Media for Mine

DESCRIPTION

1. Grade: 45#,50Mn,60Mn,65Mn,B2,B3,BL,BG2. Diameter: 15mm-150mm3. Hardness: HRC 55-654. Breakage Rate:<1%5. Impact Value: >12j/Cm^26. Falling ball times: ≥20000s

Forged(Rolling) Steel Ball Classification and Chemical Composition

| Name | C | Mn | Si | S | P | Cr |

| SY-01-45# | 0.42-0.48 | 0.50-0.80 | 0.17-0.37 | 0.35max | 0.35max | 0.15max |

| SY-02-50Mn | 0.48-0.56 | 0.65-1.00 | 0.17-0.37 | 0.35max | 0.35max | 0.15max |

| SY-03-60Mn | 0.57-0.65 | 0.70-1.10 | 0.17-0.37 | 0.35max | 0.35max | 0.25max |

| SY-04-65Mn | 0.62-0.75 | 0.90-1.20 | 0.17-0.37 | 0.35max | 0.35max | 0.25max |

| SY-05-B2 | 0.75-0.85 | 0.70-0.90 | 0.17-0.35 | 0.35max | 0.35max | 0.40-0.60 |

| SY-06-B3 | 0.50-0.65 | 0.40-1.00 | 1.35-1.85 | 0.35max | 0.35max | 0.80-1.20 |

| SY-07-BL | 0.55-0.75 | 0.65-0.85 | 0.15-0.35 | 0.35max | 0.35max | 0.70-1.20 |

| SY-08-BG | 0.90-1.05 | 0.35-0.95 | 0.15-0.35 | 0.35max | 0.35max | 1.0-1.70 |

Two hot sale grinding balls specially designed for ball mill and SAG mill

| Diamater mm | SY-05-B2 | Application | |

| Surface | Volumetric | Ball mill with diameter 1-8m | |

| 15-40 | 60-65 | 60-65 | |

| 50-70 | 60-65 | 58-63 | |

| 80-100 | 56-63 | 54-62 | |

| Diamater mm | SY-06-B3 | Application | |

| 100 | 60-65 | 58-63 | SAG mill with diameter below 13m |

| 120 | 60-64 | 57-62 | |

| 130 | 60-63 | 56-60 | |

| 150 | 58-62 | 54-60 | |

ABOUT US

Shandong Shengye Grinding Bal Co, Ltd is a professional factory specialize in the production of forged / hot rolled grinding balls, alloy grinding steel rods for more than 10 years, annual output is 100,000 tons. we have 10 worlds advanced forging and automatic rolling production lines that can meet customers' complex demands.ShengYe has passed international and industrial certifications such as TUV ISO900, ISO14001, Iso45001, etc and also passed the double certification of SGS and BV as qualified factories. Our first-class laboratory equipped with advanced testing equipment, such as spectrometer, hardness tester, drop tester, impact tester. etc.. to ensure that our products from the raw material into the factory to the production process to the shipment of every link quality control assurance and traceability. Our customers spread all over southeast Asia, Africa, Latin America which involved more than 40 countries. We have good business cooperation with China and the world-renowned large mining companies as well as cement plants, thermal power plants and chemical plants and have received favorable comments from them.

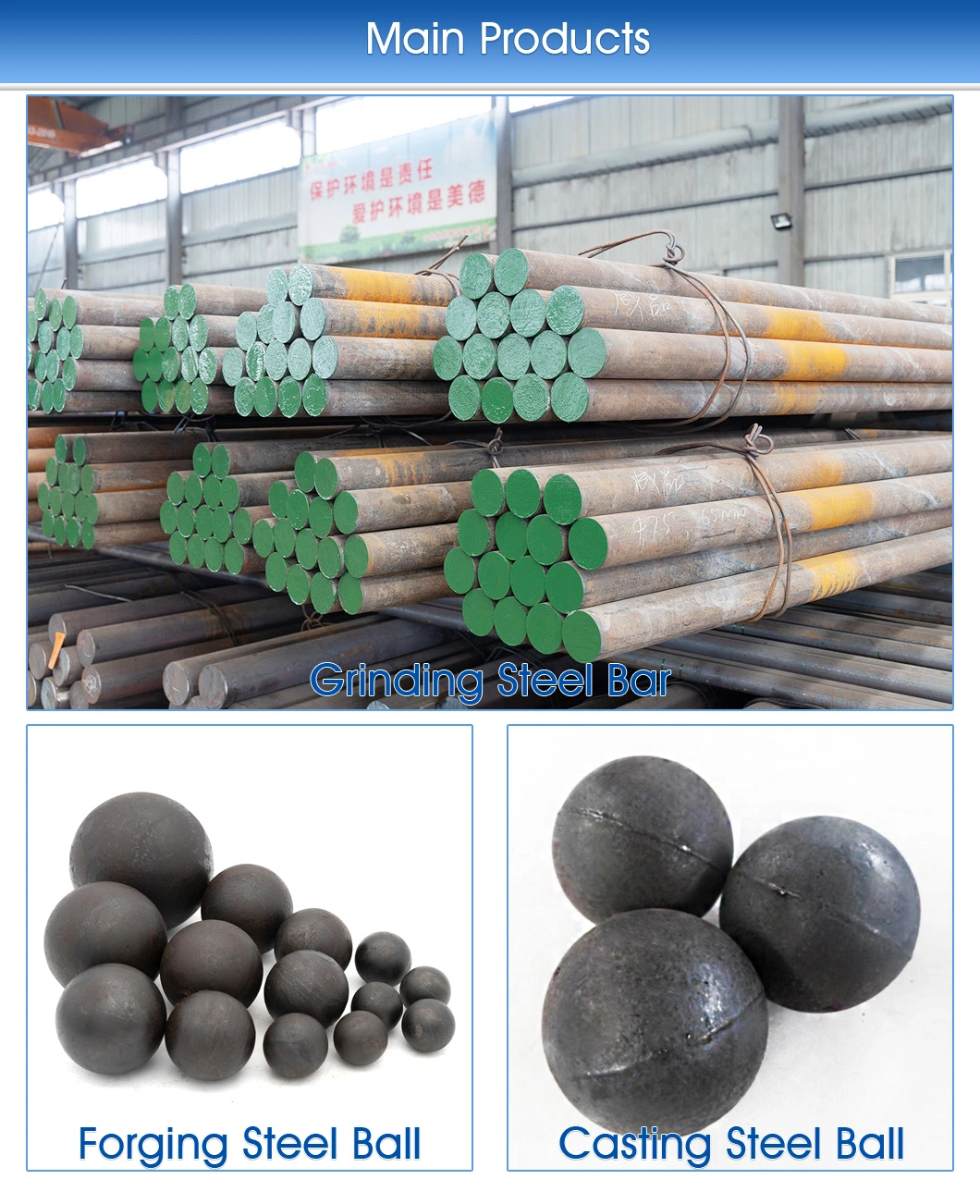

PRODUCTION PROCESSING

1.Customized production of raw materials→2.raw materials inspection→3.put the raw material into the stove and heat it to a certain temperature→4.forging / hot rolling process→5.Isothermal process→6.Quenching→7.natural cooling→8.Tempering→9.Comprehensive product inspection→10.Packaging and storage

WHY CHOOSE US

1. We are a solid grinding ball supplier with 15 years reputation guarantee;2. Advanced manufacturing techniques and complete testing equipment;3. Adequate and rich range of material stock We have the stock of common material 10,000 tons in the warehouse, which enables us to match materials quickly or customize special materials from steel mills according to customers' demand. We can guarantee the product performance since we are equipped with first-class laboratory detection and strong quality team.4. Fast delivery6 high-speed automatic production lines and 4 hammer-forged production lines with an annual output of 100,000t ensure our faster delivery. We have running stock of 10000tons/month, we can meet your demand for either bulk procurement or small orders of high frequency.5. Quality assurance

6. Better service system

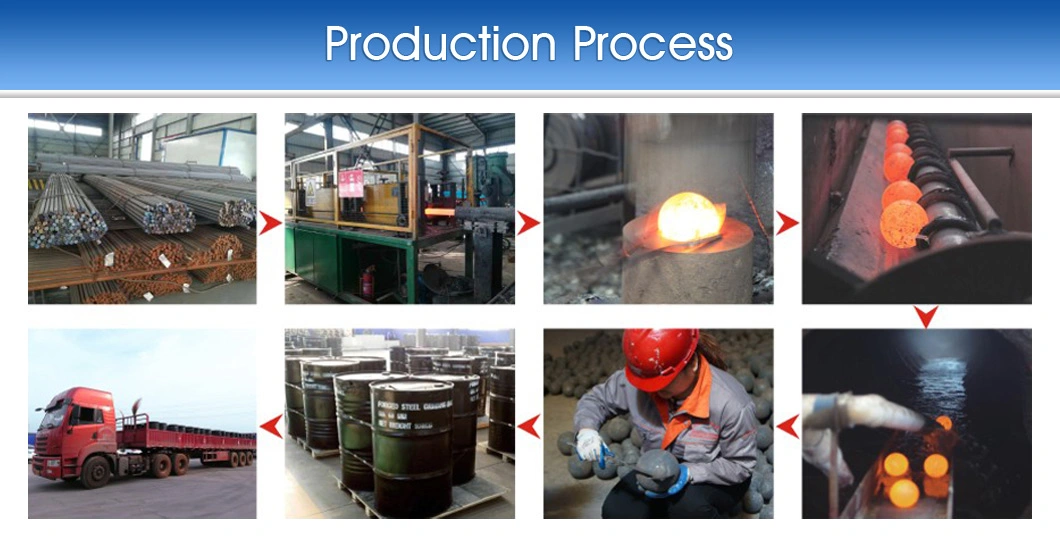

QUALITY ASSURANCE 1. The highest quality of raw materialWe only purchase directly from large regular steel groups in China. And all raw materials are strictly inspected before entering the warehouse.2. Advanced production lines and experienced operatorsShengYe has 6 high-speed automatic production lines and 4 hammer-forged production lines with an annual output of 100,000t. Covering the specifications of DIA15-150 mm and all materials to meet customers' different requirements. All of the operators are well trained and have more than 5 years of experience in forging ball manufacturing.3. Unique heat treatment technical ensure the grinding ball performanceHeat treatment is another important factor that will influence grinding balls' quality. The high-quality grinding balls shall be tough and uniform in hardness. ShengYe has adopted unique complex heat treatment craft. By repeated quenching, the quenching liquid temperature control, the continuous tempering, etc., the steel ball has better performance in the volume hardness uniformity and the overall wear resistance.4. Complete testing equipmentWe have a world-class laboratory and complete test equipment. We are able to make tests of chemical elements, mechanical properties, microstructure and so on. It helps us to get accurate data verification from raw materials to finished products,as well as the continuous data accumulation for our technical department and clients so as to develop new materials and crafts.5. Strictly comply with the quality systemWe have passed international and industrial certifications such as TUV ISO900, ISO14001, Iso45001, etc and also passed the double certification of SGS and BV as qualified factories.

PACKING AND DELIVERY

1. Ocean shipping2. Customers designated transportation mode. 3. Packing Details: A. Steel drums (850-930kgs/drum) b. Flexible container bags(1ton/bag)4. Delivery Details: Within 15-20 days after received the payment or LC at sight.

OUR SERVICE SYSTEM

1. Fast start orders 24 hours a day2. Customized raw material service 3. Free samples for evaluation4. Grinding technical guidance15 years of experience in overseas services let us fully understand the complexity and diversity of customers' requirements in different aspects, what we do most is help customers improve grinding efficiency and reduce cost.5. After-sales regular return visit and follow-upSolicit comments from the buyer and satisfied the buyer's reasonable requirements to improve product-related processes.OUR PARTNER

Our customers spread all over southeast Asia, Africa, Latin America which involved more than 40 countries. We have good business cooperation with China and the world-renowned large mining companies such as Goldfields, Glencore, First Quantum Minerals, CHALCO, Western Mining, etc.

FAQ

Q1: What is the advantage of your company?

A: We are a professional steel ball manufacturers, which have 15 years of production experience. We also have Hi-Tech and capable production line. Q2. In which countries are your products sold?

A: Our products are exported to over 40 countries and regions including USA, Republic of Korea, Japan, Malaysia, Australia, Canada and South Africa, etc., well and universally received by clients. In order to better serve customers, we have set up the office in Malaysia, Chile, United States and Spain. Q3: Are you trading company or manufacturer?

A: We are factory. Q4: How long is your delivery time?

A: Generally it is 5-10 days if the goods are in stock. Or it is 15-20 days if the goods are not in stock, It is according to quantity. Q5: Do you provide samples? Is it free or extra?

A: Yes, we could offer the sample for free charge but do not pay the cost of freight. Q6: What is your terms of payment?

A: Payment<=1000USD, 100% in advance. Payment>=1000USD, 30% T/T in advance, Balance before shippment. If you have another question, pls feel free to contact us as below: Linda/ MANAGERSHANDONG SHENGYE GRINDING BALL

You may also like

Send inquiry

Send now