10mm-160mm Grinding Media Steel Forged Ball for Ball Mill

Basic Info

| Model NO. | DIA 10mm-200mm |

| Material | Alloy Steel, Round Steel, Steel Iron |

| Content | >90% |

| Usage | Construction, Machinery, Chemical, Grind, Refractory Material, Mining, Cement Plant, Power Industry |

| Processing Type | Forging, Rolling, Casting |

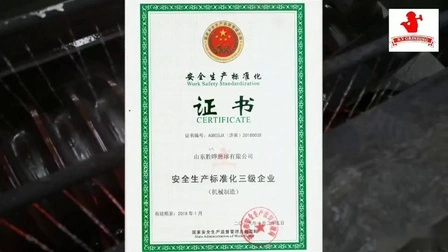

| Size | Dia 20mm-150mm |

| Color | Black |

| Customized | Customized |

| Product Name | Grinding Stee Ball |

| Process | Forged / Hot Rolled / Cast |

| Certification | TUV ISO 9001, ISO14001, ISO45001, SGS, BV |

| Service | Free Samples |

| Heat Treatment | Quenching+Tempering |

| Hardness | 60-66HRC |

| Breakage Rate | <0.5% |

| Impact Toughness | >12ak.J/Cm^2 |

| Quality Control | Professional Inspection |

| Advantage | Long Service Life & Good Wear Rate |

| Application | Ball Mill, Sag Mills, Vertimills, Mineral Process |

| Transport Package | Steel Drums & Flexible Container Bags |

| Specification | 45#-BG |

| Trademark | ShengYe |

| Origin | Shandong, China |

| HS Code | 73261100 |

| Production Capacity | 100, 000 Tons |

Product Description

10mm-160mm Grinding Media Steel Forged Ball for Ball MillProduct Description

REGULAR SIZE OF FORGED STEEL GRINDING BALL

| 10mm (2/5 Inch) | 15mm (3/5 Inch) | 20mm (4/5 Inch) | 25mm (1 Inch) | 30mm (1¼ Inch) | 40mm (1½ Inch) | 50mm (2 Inch) | 60mm (2½ Inch) | 65mm | 70mm (2¾ Inch) |

| 80mm (3¼Inch) | 90mm (3¾Inch) | 100mm (4 Inch) | 110mm (4⅓ Inch) | 120mm (5 Inch) | 125mm | 130mm | 140mm (5½ Inch) | 150mm (6 Inch) | 160mm (6⅓ Inch) |

FORGED GRINDING BALL CHEMICAL COMPOSITION

| SPEC. | C | Mn | Si | S | P | Cr |

| SY-01-45# | 0.42-0.48 | 0.50-0.80 | 0.17-0.37 | 0.05max | 0.05max | 0.15max |

| SY-02-50Mn | 0.48-0.56 | 0.65-1.00 | 0.17-0.37 | 0.05max | 0.05max | 0.15max |

| SY-03-60Mn | 0.57-0.65 | 0.70-1.10 | 0.17-0.37 | 0.05max | 0.05max | 0.25max |

| SY-04-65Mn | 0.62-0.75 | 0.90-1.20 | 0.17-0.37 | 0.05max | 0.05max | 0.25max |

| SY-05-B2 | 0.75-0.85 | 0.70-0.90 | 0.17-0.35 | 0.05max | 0.05max | 0.40-0.60 |

| SY-06-B3 | 0.50-0.65 | 0.40-1.00 | 1.35-1.85 | 0.05max | 0.05max | 0.80-1.20 |

| SY-07-BL | 0.55-0.75 | 0.65-0.85 | 0.15-0.35 | 0.05max | 0.05max | 0.70-1.20 |

| SY-08-BG | 0.90-1.05 | 0.35-0.95 | 0.15-0.35 | 0.05max | 0.05max | 1.0-1.70 |

FORGED GRINDING BALL PERFORMANCE

| SPEC. | Impact Value AK.J/cm2 | Dropping test(sm) | Hardness | |||||

| Ф25-50(1"-2") | Ф60-90(2.5"-3.5") | Ф100-150(4"-6") | ||||||

| Surface | Core | Surface | Core | Surface | Core | |||

| SY-01-45# | ≥12 | ≥20,000 | ≥55 | ≥38 | ≥50 | ≥35 | ≥45 | ≥25 |

| SY-02-50Mn | ≥12 | ≥20,000 | ≥56 | ≥40 | ≥56 | ≥35 | ≥50 | ≥30 |

| SY-03-60Mn | ≥12 | ≥20,000 | ≥58 | ≥45 | ≥58 | ≥38 | ≥52 | ≥35 |

| SY-04-65Mn | ≥12 | ≥20,000 | ≥60 | ≥52 | ≥60 | ≥42 | ≥53 | ≥36 |

| SY-05-B2 | ≥12 | ≥20,000 | ≥60 | ≥60 | ≥60 | ≥54 | ≥55 | ≥48 |

| SY-06-B3 | ≥12 | ≥20,000 | ≥60 | ≥60 | ≥60 | ≥54 | ≥58 | ≥53 |

| SY-07-BL | ≥12 | ≥20,000 | ≥60 | ≥60 | ≥60 | ≥54 | ≥58 | ≥55 |

| SY-08-BG | ≥12 | ≥20,000 | ≥60 | ≥60 | ≥60 | ≥60 | ≥60 | ≥60 |

Get Wear-Resistant Grinding Ball Quotes

Please click the button "contact now", Manager Ina Guan will reply your inquiry.In order to get a quick quote, you can pass your detailed request to us. Like the grinding ball size, qty, chemical composition, hardness requirements, incoterms, etc. Also submit your company name, email address, phone number. We will send you detailed quotation list within 24 hours.Or you can choose click the button"Chat with supplier", Manager Ina Guan will answer your inquiry.

1) Tuv ISO9001 qualified factory2) Covering an area of 15,000m2, with 100+staffs3) Capacity: 150,000 tons4) Awarded 21 technical patents5) Established first workshop in 2000Shandong Shengye Grinding Ball is located in Jinan City Shandong Province of China. Our feature products include Grinding Steel Balls and Grinding Rods. All of our products are produced in our workshops by a dynamic team of savvy engineers and skilled workers who have been solely devoted to this field for 10~20 years. We are one of the biggest Grinding Media workshops among our peers in China. We own 3 workshops that cover 10 world advanced horizontal forging and automatic rolling production lines, and 2 innovatively developed new Grinding Steel Rod production lines.Our first-class lab and QC system enable us to guarantee the high-quality standards of products, in the meantime, the database we recorded helps us to do analyses for constantly optimizing the production technology.We believe that providing high-quality products to help customers reduce operating costs is the first step to successful cooperation. Another key element is to listen to our customers' expectations and find the possibility of further improvement. We put ourselves in a position as a trusted partner more than a grinding media supplier. We are more about how to make our customers more profitable.

Quality Assurance1. Purchasing with quality, control the quality activity more on supply Chain and raw material2. Establish the toal quality roles and responsible for every production link3. Conduct the total quality management4. Strictly carry out the quality control procedure5. Testing SystemIncoming raw material testingSurface hardness testingCore hardness testingChemical composition testingImpact testingOther testing required by customer

1) Balls can be provided in 1 or 2 tons flexible container bag with secure lifting straps. Bags can be strapped onto wooden pallets as per demand.2) Balls can be provided in steel drums, 850- 930KGS/DRUM. Drums can be strapped onto wooden pallets as per demand.3) Balls can be transported in bulk by open top trucks or in 20ft container.

1) 3 fixed long-term logistic partners, satisfy sea or rail transportation under different incoterms

2) Establish the key roles to responsible for delivery & logistics3) management Create shipping files4) Implement logistics tracking serviceShengYe Certificates1) German TUVISO9001quality system certification2) ISO14001environmental management system certification3) ISO45001occupational health and safety management system certification4) AAA Credit Enterprise5) SGS Audited Supplier6) Level 3 Enterprise of Safety Production Standardization

Our CustomerOur customers come from more than 40 countries where grinding media is in high demand such as Japan, Korea, Malaysia, India, Mongolia, Peru, Spain, Mexico, Cuba, Colombia, Morocco, Ghana, Congo, Mauritania, Sudan,PNG, Kazakhstan, etc. Our key customers are distributed in South America, North America and Africa, share more than 60% of total sales. In order to better serve customers, we have set up offices in Malaysia, Chile, United States and Spain.