High Precision Chrome/Stainless/Carbon/Metal/Steel Ball for Ball Bearing/Auto Parts/Cosmetic/Car/Motorcycle Parts/Dirt Bike Parts/Deep Groove Bearing Ball

Basic Info

| Model NO. | 668 |

| Customized | Customized |

| Certification | ISO, IATF 16949 |

| Standard Parts | Yes |

| Universal | Yes |

| Type | Bearing Ball |

| Material | Chrome Steel |

| Size | 2-25.4mm |

| Drade | G10-G1000 |

| Hardness | 26-66 HRC |

| Application | Bearing, Power Tool, Automotive and So on |

| Shape | Solid Round Stainless Steel Ball |

| Company | Foison |

| Shipping | Sea Freight, Air Transport |

| Payment | Bank Transfer/Paypal |

| Delivery Time | Stock Within a Short Time or 30 Days |

| Packing | Box, Plastic Bag, Steel Drum |

| Customize | Yes |

| Color | Sliver |

| Quality | Very Good |

| Capacity | 500 Tons Per Month |

| Chemical Composition | C, Si, Mn, Cr, P, S |

| Transport Package | Box, Plastic Bag, Steel Drum |

| Specification | G10-G1000 |

| Trademark | Foison |

| Origin | Taian, China |

| HS Code | 848291 |

| Production Capacity | 500000000 Pes |

Product Description

Product Description| Product name | Stainless steel ball | |||

| Delivery time | 7~15 days | |||

| Port | Qingdao | |||

| Material | 440 stainless steel/9Cr18/304/306 | |||

| Size | 1mm~63.5mm | |||

| Grade | G10-G1000 | |||

| Place of origin | China Taian | |||

| Brand name | FOISON | |||

| Layer | Polishing | |||

| Product name | Chrome steel ball | |||

| Delivery time | 7~15 days | |||

| Port | Qingdao | |||

| Material | Gcr15 52100 | |||

| Size | 0.8mm~80mm | |||

| Grade | G10-G1000 | |||

| Place of origin | China Taian | |||

| Brand name | FOISON | |||

| Layer | Polishing | |||

| Product name | Carbon steel ball | |||

| Delivery time | 7~15 days | |||

| Port | Qingdao | |||

| Material | Q195 Q235 15A C80 C82 | |||

| Size | 0.8mm~80mm | |||

| Grade | G10-G1000 | |||

| Place of origin | China Taian | |||

| Brand name | FOISON | |||

| Layer | Polishing | |||

Applications: cosmetics, automobile transmission parts, bearings, sliding rails, rotating parts of furniture and electrical appliances, medical treatment, grinding, counterweights, etc.

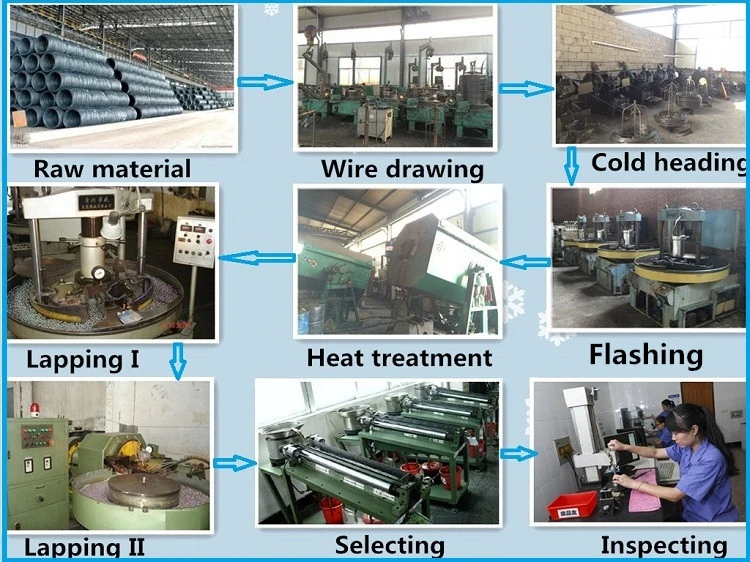

Manufacturing processThe Production Process of steel ball

Heading:

In the first step, heading machines cut wire into short lengths and form it into spherical shapes between dies.

Deflashing:

The flash line, a ridge left by the forming dies, is removed as balls roll between heavy,cast iron plates.

Soft Grinding:

Similar to deflashing, except that a grinding stone is used to improve precision.

Heat-treating:

Carbon steel balls are next carburized and hardened. Heat treatment imparts the desired hardness and case depth.

Descaling:

This step removes the residues and by-products from the heat-treating process.

Hard Grinding:

Slow, meticulous grinding assures proper sizing and sphericity, with tolerances as closeas ±.0001".

Lapping:

Several proprietary lapping processes can bring balls to the requirements of ISO 3290 Grade10 - 48.

Finishing:

Proprietary chemical and mechanical processes give the balls their final micro-smoothed finish, for increased wear resistance and product longevity.

CertificationsISO 9001 & IATF16949 of our own factory named-Huatong

Packaging & ShippingPackaging:

A. Steel Drum packing 1) 250kg per steel drum;2) Four steel drums in one pallet;3) Drum with pallet size: 75CM*75CM*65CM.B. Plywood Box packing1) 40 cartons/woven bag in one plywood box;2) Plywood box size:80CM*65CM*80CM.C. Recommended to use 20"FT container, Maximum loading capacity of 24 tons.D. 20"FT container loading of 24 tons Total: 24 Plywood Box or Drum.

Shipping:

Shipping time: It will takes about 20-25days if by sea, It will takes about 5-7days if by air,By DHL,UPS,FEDEX,TNT,It will takes about 4-6 working days except festival and holiday.1.If the quantity of order is not very big, we will send them to you by express delivery, such as TNT,DHL,UPS or EMS etc.2.If order is big, we will advise you use Air Freight or Sea Freight. It through your pointed forwarders freight. FOB port is Ningbo or Shanghai.3.If you don't have your specified forwarders freight, we can find the cheapest forwarders freight to ship the goods to your point port.4.The balance payment should be paid before delivery to you.